Filamenti yosinthasintha ya 3D TPU yabuluu 1.75mm Shore A 95

Zinthu Zamalonda

| Mtundu | Torwell |

| Zinthu Zofunika | Polyurethane ya Thermoplastic yapamwamba kwambiri |

| M'mimba mwake | 1.75mm/2.85mm/3.0mm |

| Kalemeredwe kake konse | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Malemeledwe onse | 1.2Kg/spool |

| Kulekerera | ± 0.05mm |

| Utali | 1.75mm(1kg) = 330m |

| Malo Osungira Zinthu | Youma komanso yopatsa mpweya wabwino |

| Malo Oumitsira | 65˚C kwa maola 8 |

| Zipangizo zothandizira | Pakani ndi Torwell HIPS, Torwell PVA |

| Kuvomerezeka kwa Chitsimikizo | CE, MSDS, Reach, FDA, TUV ndi SGS |

| Yogwirizana ndi | Makerbot, UP, Felix, Reprap, Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker ndi ma printer ena aliwonse a FDM 3D |

| Phukusi | 1kg/spool; 8spools/ctn kapena 10spools/ctn thumba la pulasitiki lotsekedwa ndi mankhwala otsukira mano |

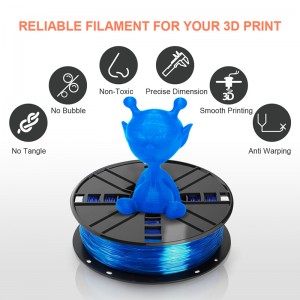

TorwellUlusi wa TPU umadziwika ndi mphamvu zake zambiri komanso kusinthasintha kwake, monga pulasitiki ndi rabala wosakanizidwa.

95A TPU ili ndi kukana kwambiri kukanda komanso kupsinjika kochepa poyerekeza ndi zida za rabara, makamaka pakakhala zinthu zambiri zodzaza.

Poyerekeza ndi ulusi wofala kwambiri monga PLA ndi ABS, TPU iyenera kuyendetsedwa pang'onopang'ono kwambiri.

Mitundu Ina

Mtundu Ulipo

| Mtundu woyambira | Woyera, Wakuda, Wofiira, Wabuluu, Wachikasu, Wobiriwira, Imvi, Lalanje, Wowonekera |

| Landirani Mtundu wa PMS wa Makasitomala | |

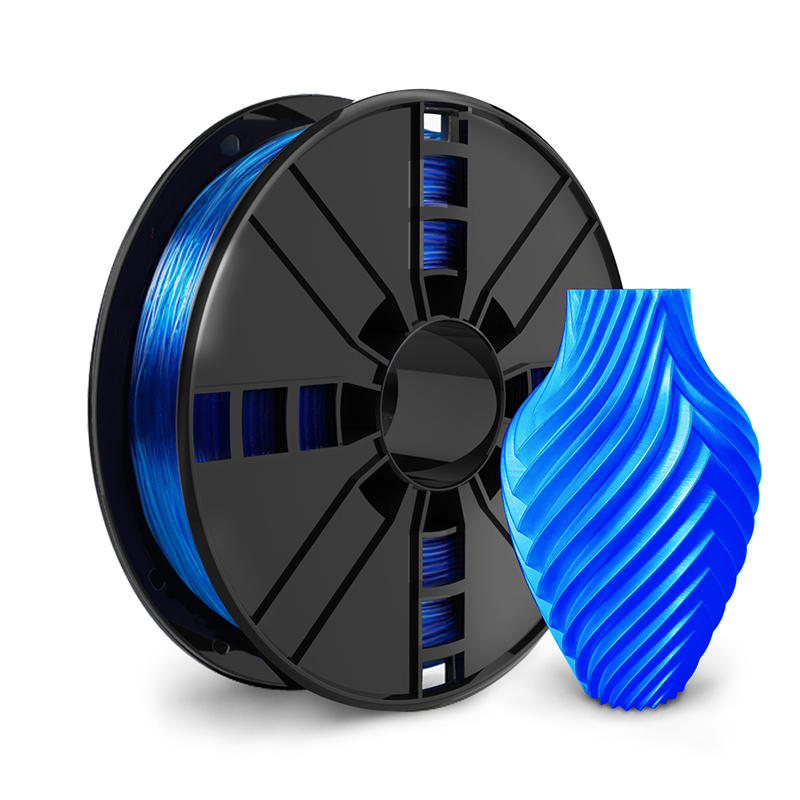

Chiwonetsero cha Zitsanzo

Phukusi

Mpukutu wa 1kgTPU ya ulusi wa 3Dyokhala ndi desiccant mkatichotsukira mpweya phukusi

Bokosi lililonse lokhala ndi bokosi limodzi (bokosi la Torwell, bokosi losalowerera, kapena bokosi losinthidwa)kupezeka)

Mabokosi 8 pa katoni iliyonse (kukula kwa katoni 44x44x19cm)

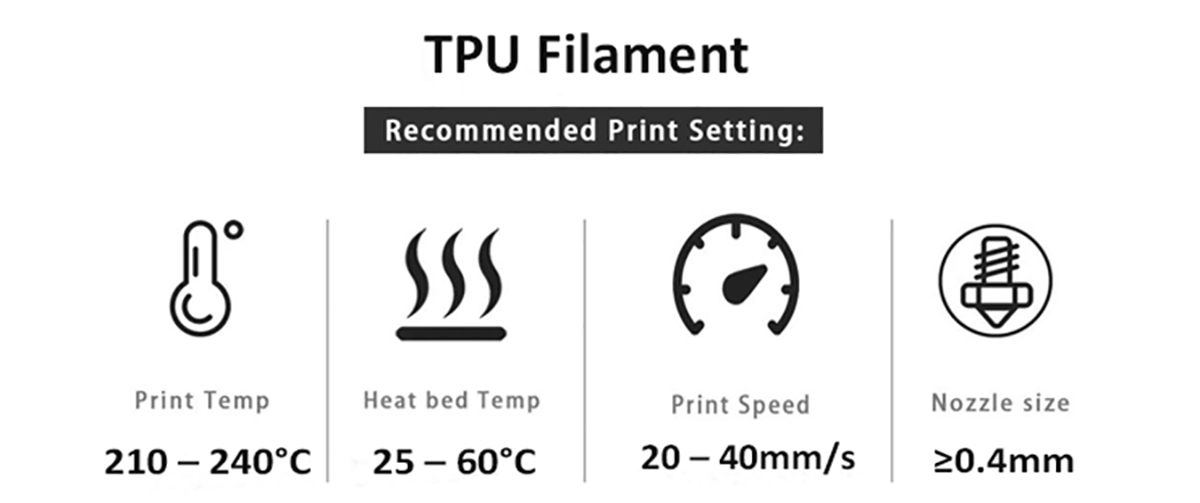

Akulimbikitsidwa kwa osindikiza omwe ali ndi chotulutsira chowongolera mwachindunji, Ma Nozzle a 0.4 ~ 0.8mm.

Ndi Bowden extruder mutha kulabadira kwambiri malangizo awa:

- Sindikizani pang'onopang'ono 20-40 mm/s Liwiro losindikiza

- Zokonda za gawo loyamba. (Kutalika 100% M'lifupi 150% liwiro 50% mwachitsanzo)

- Kubweza kwalephereka. Izi zimachepetsa zotsatira zosindikiza zosokoneza, zomangirira kapena zotulutsa utsi.

- Kuchulukitsa (Ngati mukufuna). Kuyika pa 1.1 kungathandize kuti ulusi ugwirizane bwino. - Kuzimitsa fani pambuyo pa gawo loyamba.

Ngati mukuvutika kusindikiza ndi ulusi wofewa, choyamba, komanso chofunika kwambiri, kuchepetsa kusindikiza, kuthamanga pa 20mm/s kudzagwira ntchito bwino kwambiri.

Ndikofunikira kwambiri poika ulusi kuti uyambe kutulutsa. Mukangoona ulusi ukutuluka, gwirani nozzle. Mbali yonyamula imakankhira ulusi mwachangu kuposa momwe umasindikizidwira nthawi zonse ndipo izi zingayambitse kuti ugwire mu giya yotulutsira.

Komanso perekani ulusi mwachindunji ku chotulutsira ulusi, osati kudzera mu chubu chodyetsera. Izi zimachepetsa kukoka kwa ulusi komwe kungayambitse kuti giya igwedezeke pa ulusi.

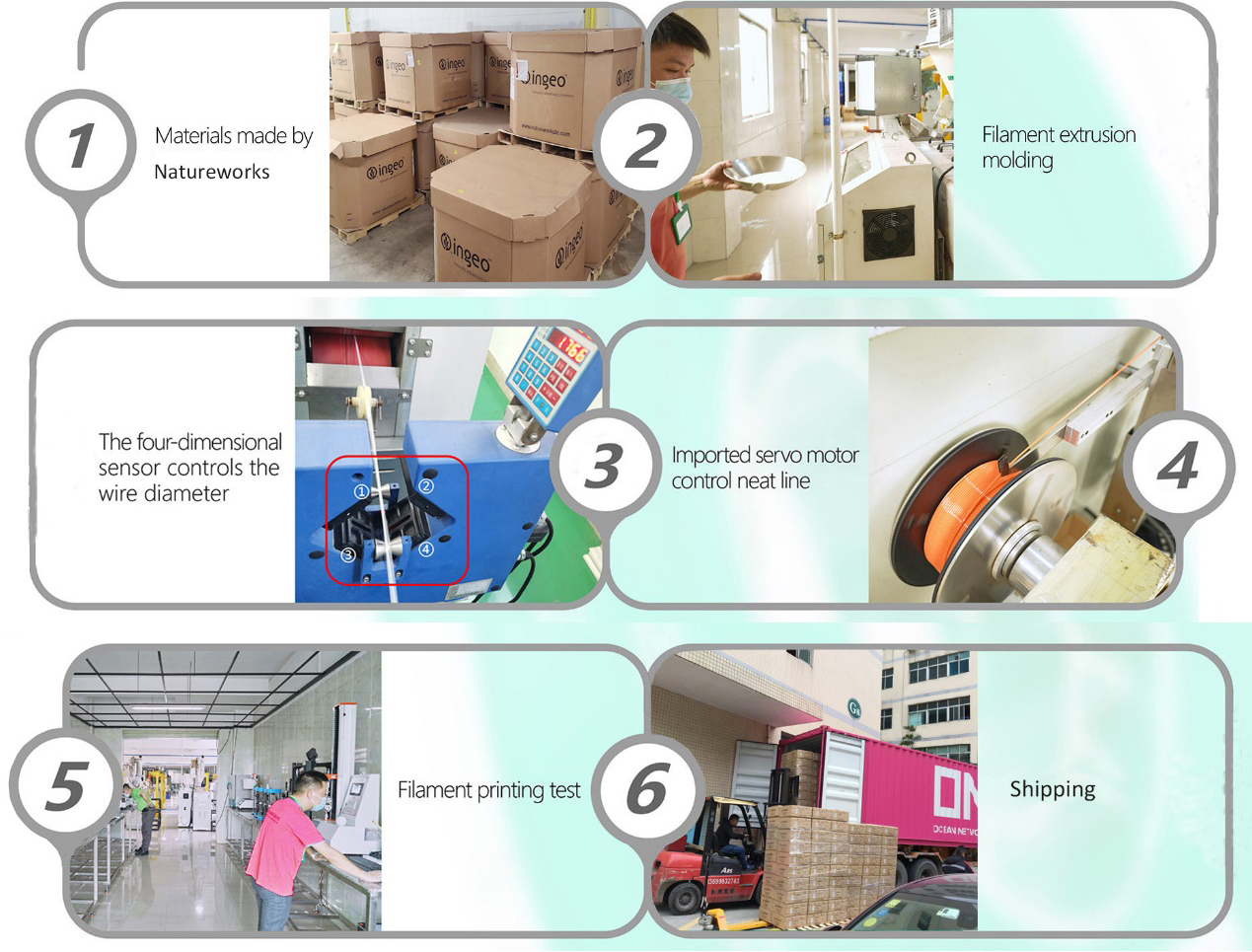

Malo Opangira Mafakitale

FAQ

A: Inde, nsalu iliyonse ya TPU ikhoza kupakidwa utoto. Ndimagwiritsa ntchito "Tulip Colorshot Fabric Spray Paint". Imamatira bwino ku gawo la TPU ndipo siikukuta m'manja mwanu kapena zovala. Imauma pakatha ola limodzi kapena kuchepera. Ndimagwiritsanso ntchito heat gun kuti iume pakatha mphindi zochepa. Muthanso kugwiritsa ntchito blow dryer. Mutha kusankha ulusi wa TPU wa imvi ngati mtundu wosalowerera, kenako ndikuupaka ndi utoto womwe uli pamwambapa mumitundu yosiyanasiyana yomwe amapereka. Ndicho chimene ndimachita ndipo chimagwira ntchito bwino.

A: TPU idachokera kwa TorwellIli ndi fungo lochepa kwambiri kuposa PLA. Ilibe fungo lomwe ndalionapo kale ndipo ndimatsegula chosindikizira ndikamagwiritsa ntchito Flex. Ponena za poizoni sindikudziwa, koma fungo lake si vuto.

A: TPU imagwira ntchito bwino kuposa PLA nthawi iliyonse ikafunika kusinthasintha. TPU imapereka kulimba kwambiri komanso kukana kukhudza kwambiri. PLA imakondedwa kuposa TPU pamene kusindikiza kosavuta ndikokonda, kuti zinthu zikhale zolimba komanso zapamwamba. TPU ingagwiritsidwe ntchito m'zigawo zogwira ntchito ngati pulogalamu.

A: Inde, TPU ndi ulusi wosatentha womwe uli ndi kutentha kwa galasi kosintha kwa 60 DegC. Kutentha kosungunuka kwa TPU ndi kokwera kuposa PLA.

A: Liwiro losindikiza la ulusi wa TPU limasiyana pakati pa mamilimita 15-30 pa sekondi popanda kusokoneza ubwino.

| Kuchulukana | 1.21 g/cm3 |

| Chiyerekezo cha Kuthamanga kwa Sungunulani (g/10min) | 1.5(190℃/2.16kg) |

| Kulimba kwa Pagombe | 95A |

| Kulimba kwamakokedwe | 32 MPa |

| Kutalika pa nthawi yopuma | 800% |

| Mphamvu Yosinthasintha | / |

| Modulus Yosinthasintha | / |

| Mphamvu Yokhudza IZOD | / |

| Kulimba | 9/10 |

| Kusindikiza | 6/10 |

| Kutentha kwa Extruder (℃) | 210 – 240℃ 235℃ Yovomerezeka |

| Kutentha kwa bedi (℃) | 25 - 60°C |

| Kukula kwa Nozzle | ≥0.4mm |

| Liwiro la Fani | Pa 100% |

| Liwiro Losindikiza | 20 – 40mm/s |

| Bedi Lotentha | Zosankha |

| Malo Omangira Ovomerezeka | Galasi yokhala ndi guluu, pepala lophimba nkhope, tepi yabuluu, BuilTak, PEI |